Description

- Furnace control:

- Under the furnace

- Solid state relay

- PAD Digital control. Microprocessor. Alarm.

- Safety Shut-off

- Thermocouple break shut-off

- Turns off upon door opening

- Manufactured under the CE

- Accessories

- Ceramic tray

- Smoke chimney

- Forced smoke chimney

- Fast Cooling system

- Security class II. Over-temperature protection (OTP)

- Inlet gas entry

- Flow meter box

- Control system

- Ramp programmer up to 64 steps

- Eurotherm EPC Series + Data logger Itools sofware by Ethernet (Optional)

- Eurotherm Nanodac Series +Data logger and Itools sofware by Ethernet according AMS2750E and 21CFR Part 11 (Optional)

Standards: Ceramic and metal sintering process

Sintering furnaces for your 3D metal and ceramic printing applications.

Technical ceramics, sintering, debinding, bioceramics process

.

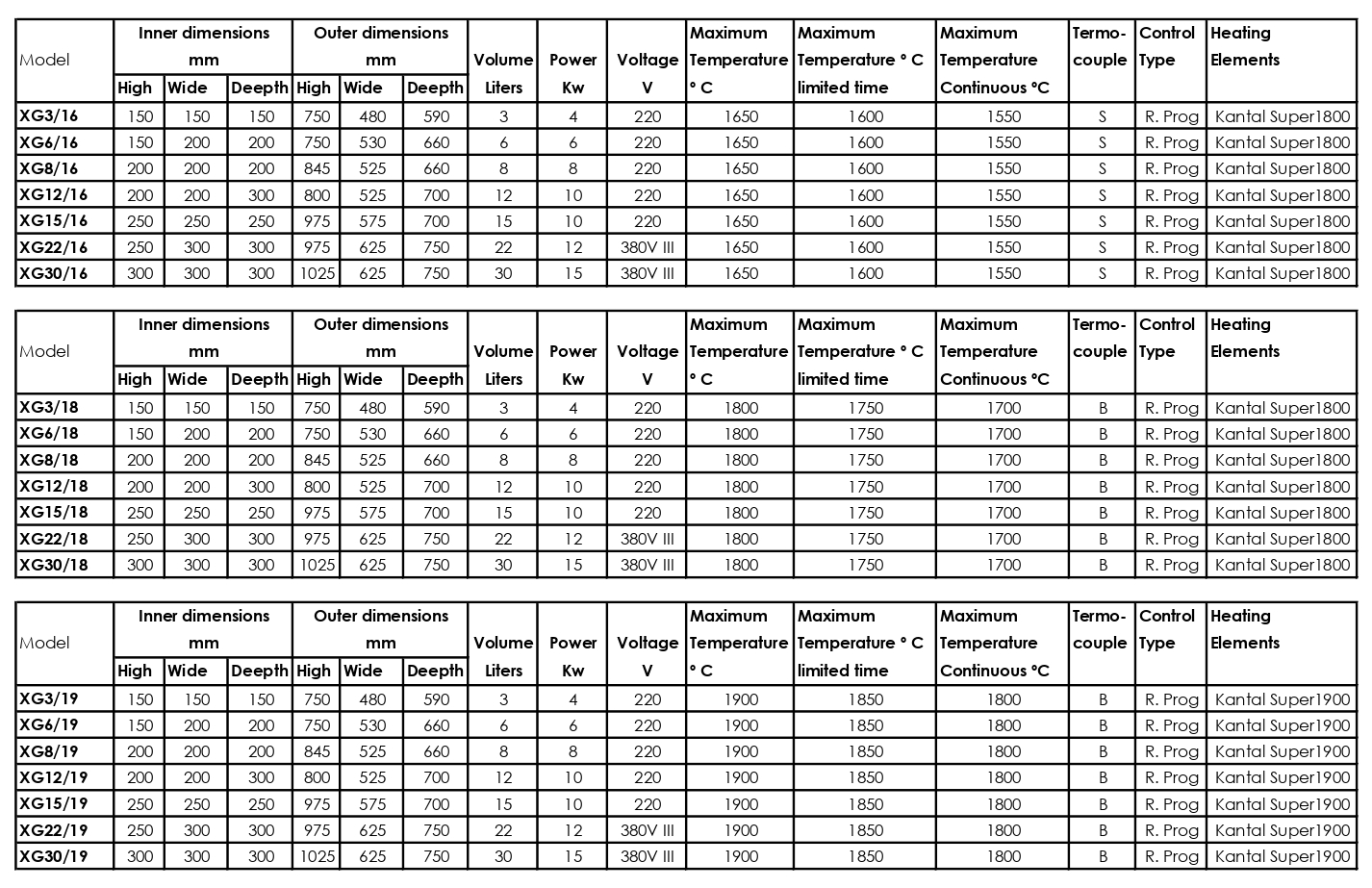

TECHNICAL DETAILS

The metal and ceramic sintering process is used to compact a powder into a solid with the application of heat. The samples are heated in a sintering furnace to a temperature lower than the melting point which causes the powder particles to bond together into a compact mass.

Hobersal offers a very complete range of furnaces for sintering, vacuum furnaces, controlled atmosphere furnaces, muffle furnaces, ovens and high temperature muffle and tube furnace

Reviews

There are no reviews yet.